In the sheet metal world, it's sometimes easier to tell the full story by showing different stages of the project. As a sheet metal fabrication shop, our team has had the opportunity to work with hundreds of companies and individuals throughout the Kansas City area. On this page, we'll continue to add photos highlighting the "Before & After" stages of various projects our team works on. For more photos of completed projects, feel free to check out our gallery HERE.

Refurbished Washer.

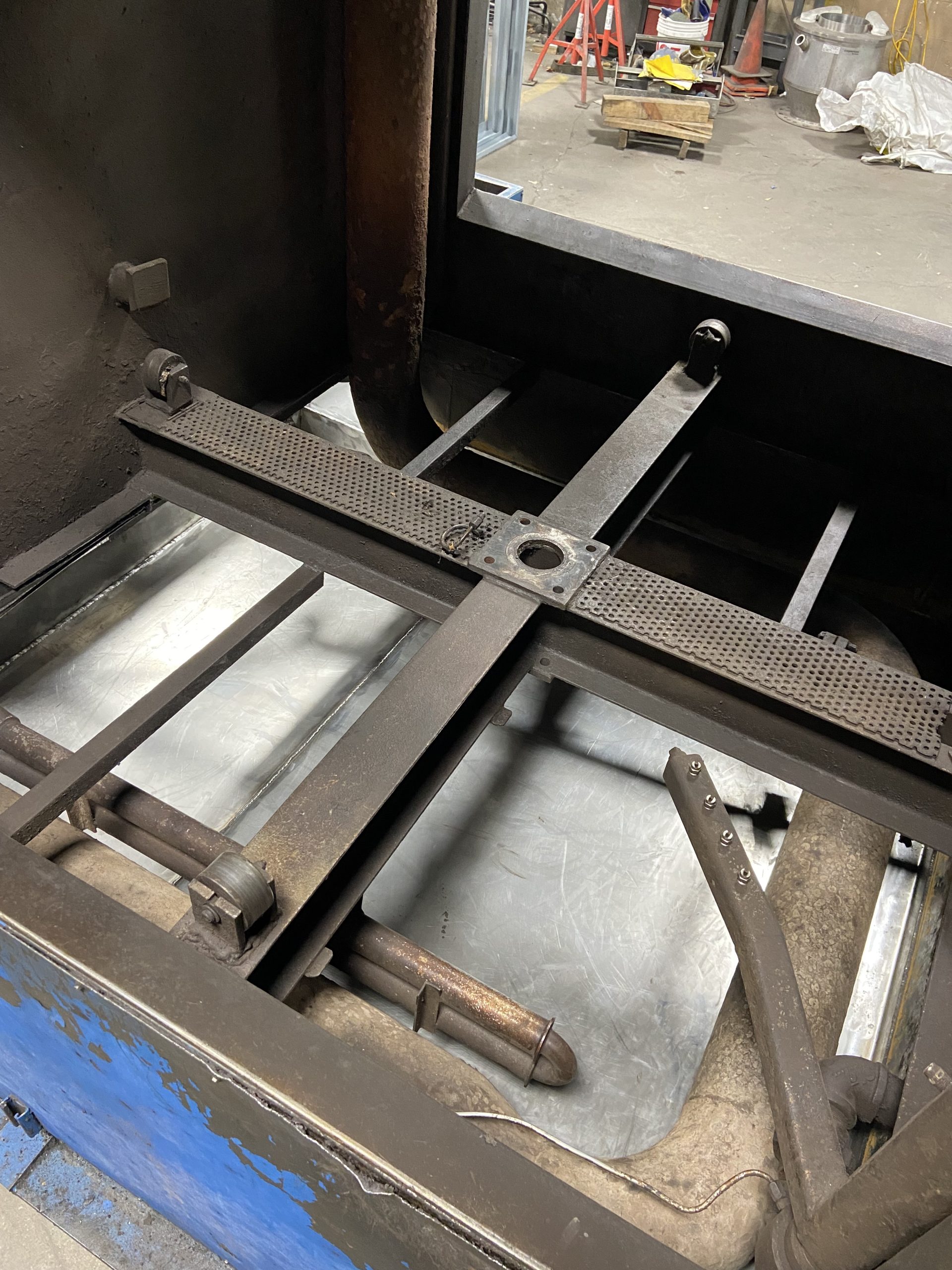

In the photos featured below, you'll find a refurbished washer project that our team worked on. Our team installed a stainless steel bottom and weir assembly. The previous flooring was made out of carbon steel. All components are 100% watertight welded.

BEFORE

AFTER

Food Grade Conical Spiral Chute.

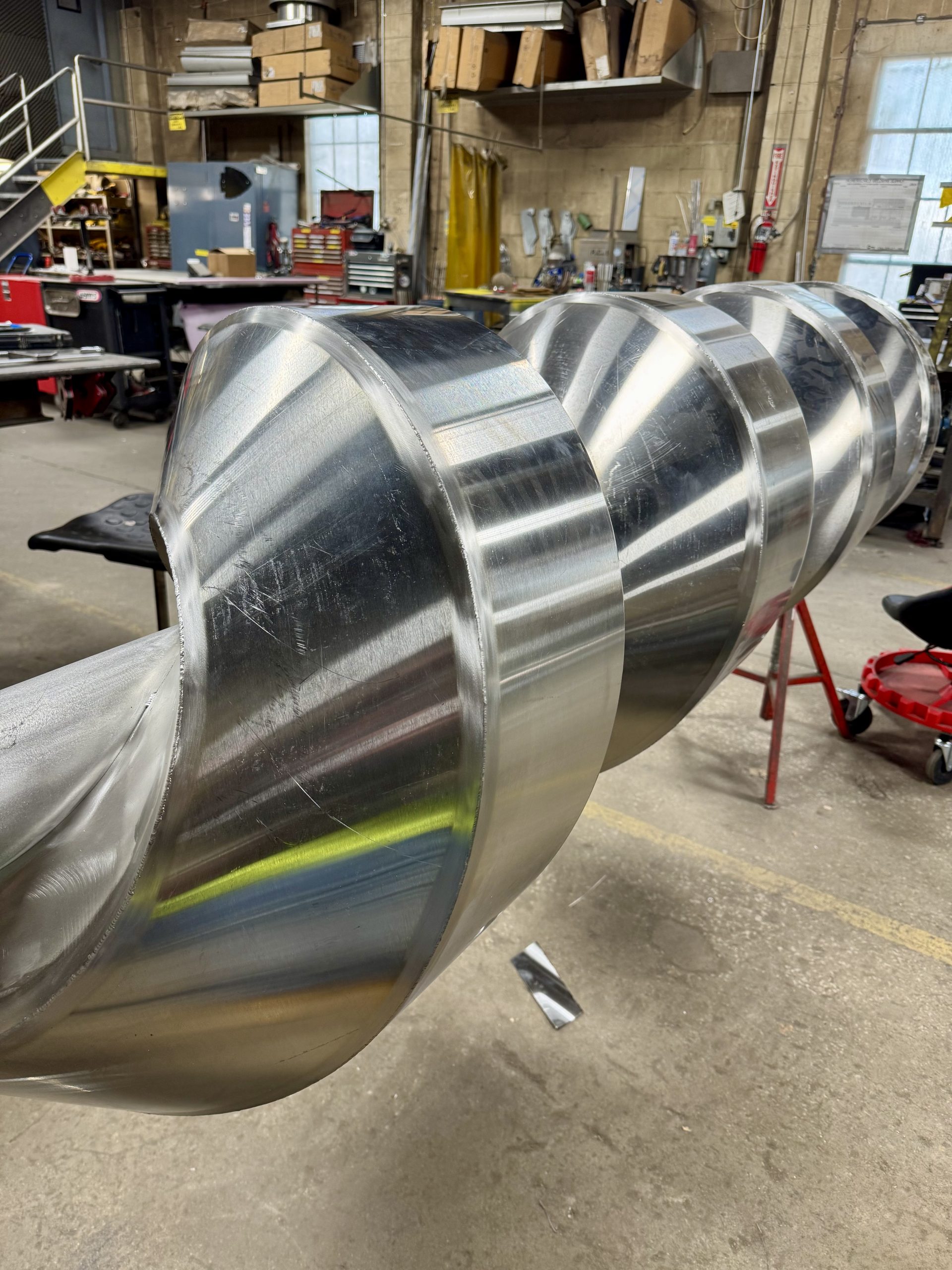

Take a look through the different stages that went into a conical spiral chute that our team crafted for a customer in the food manufacturing industry. This chute was made out of 304 stainless and up to food grade standards.

STEP 1

To provide a complete recap of this project, we'll start at the beginning stages where the conical spiral had been programmed via a CAD system. After being cut on our waterjet machine, the material was then stretch-rolled to the shape requested.

STEP 2

Next up, we welded the conical spirals together and to the center support.

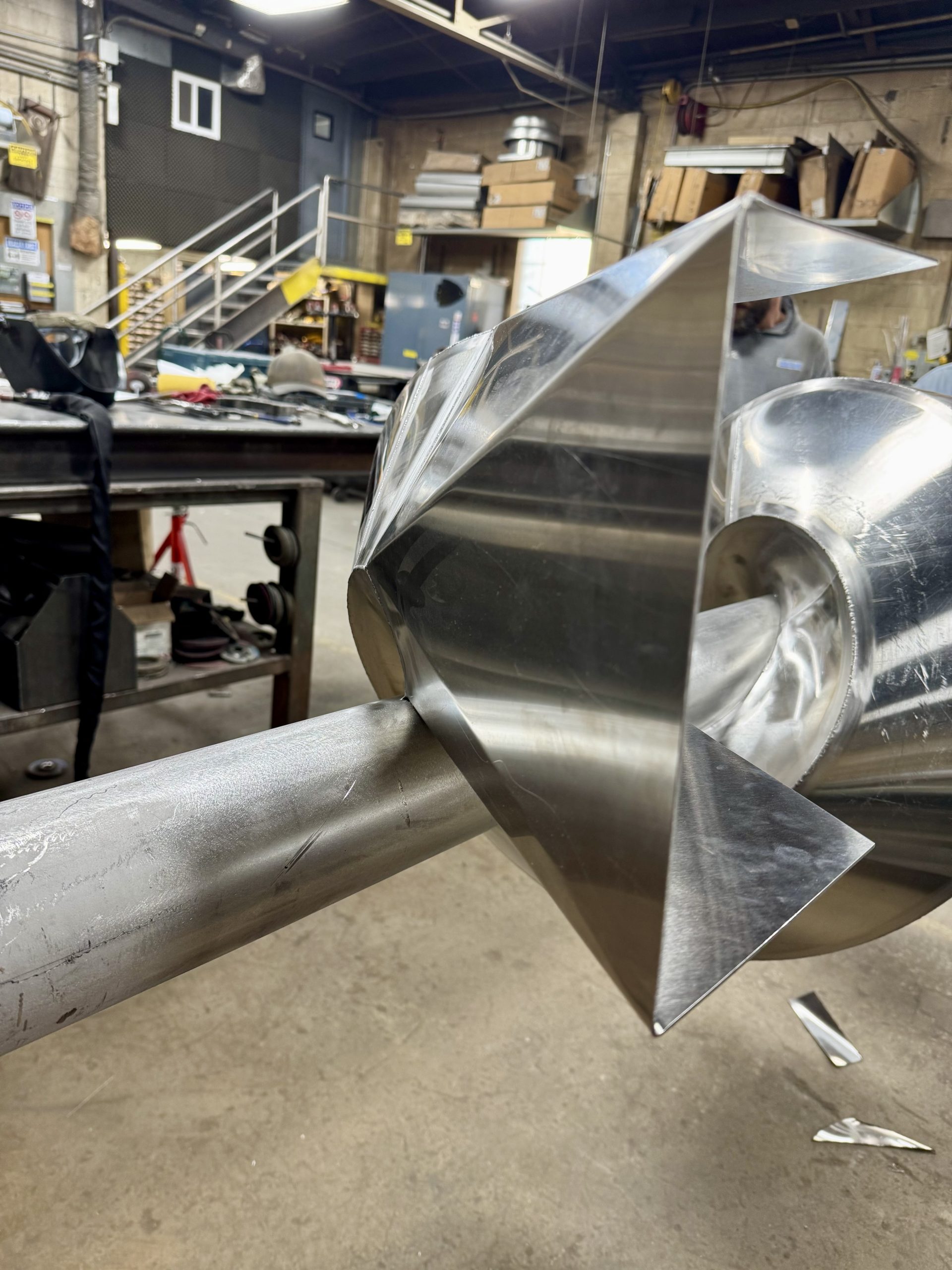

STEP 3

The sides were then welded to the outer radius to meet the design's requirements. All of the welds were completed to 110 grit food grade.

STEP 4

And just like that, the conical spiral chute is completed! The outlet chute was added to the bottom to allow for use in the food manufacturing industry.

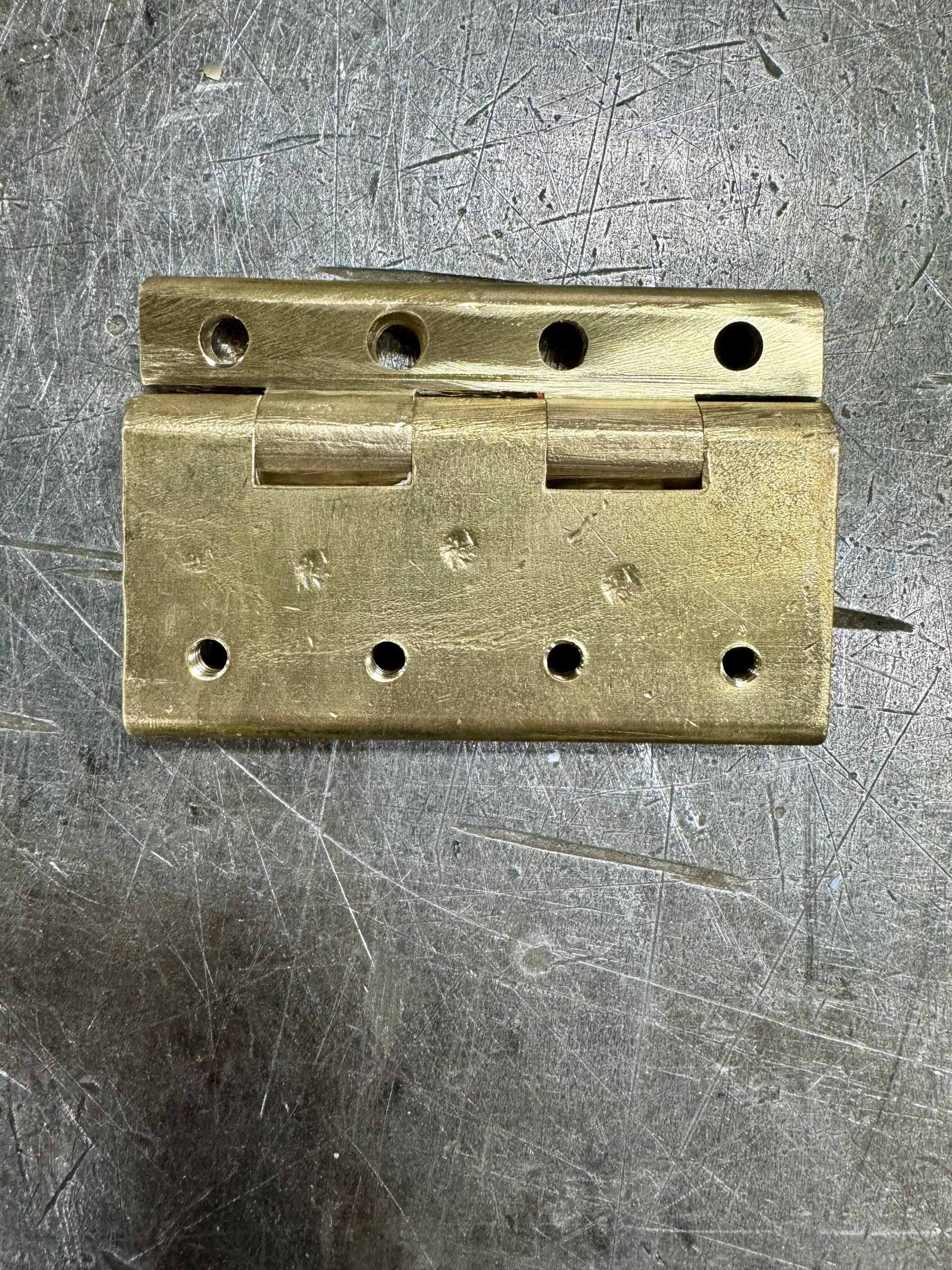

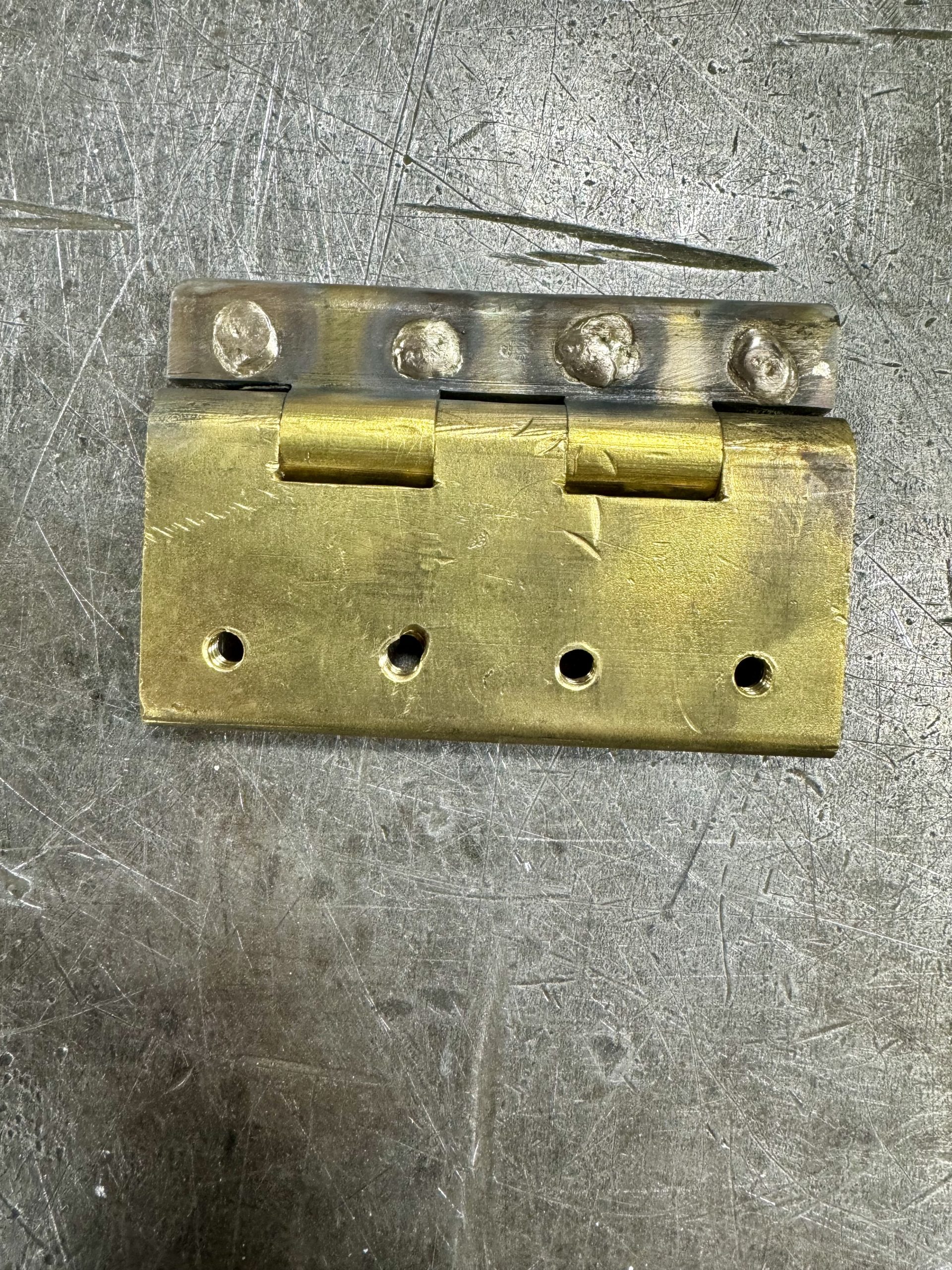

Brass Hinges.

In the photos shown below, you'll see the before and after stages of brass hinges that we reworked with brass welding.

BEFORE

AFTER

Food Grade Hopper.

Over the years, our team has had the opportunity to work with several companies in the food manufacturing industry. As you can imagine, attention to detail is a MUST for any project and is particularly important with food manufacturing products.

The project featured here is a food grade hopper with the interior welds cleaned to 110 grit. After we had completed the initial heliarc welding, our team then started the grinding process to achieve the necessary standards. For those unfamiliar with this terminology, 110 grit essentially ensures there is no possibility of contamination when the hopper is in use.