Waterjet Cutting At Its Finest.

Without a doubt, waterjet cutting has become a staple in the metal fabrication world in recent time. While the mere idea of cutting with water isn't completely new, it's safe to say the abilities of waterjet machines have significantly improved over the years. Thanks to their ability to cut at precise accuracies and much more efficient speeds, they've quickly become fan favorites. At Wil-Clair Sheet Metal, our team utilizes the Omax Maxiem 1530 Five-Axis JetMachining Center. For those unfamiliar with the Omax brand, they are certainly among the industry-leaders in the waterjet world. Their products possess the technology necessary to cut at quicker speeds, faster pierce times, with less abrasive used and ultimately greater accuracy! Furthermore, with this particular model, the five-axis system allows for a nearly endless number of possible cuts, including 3D objects.

With that in mind, you may wonder what separates the Omax Maxiem from any other waterjet machine on the market? Having operated a traditional waterjet machine at our own shop, it didn't take long for our team to realize the results were incomparable. On the points below, we highlighted some of our favorite aspects of the cutting-edge machine.

When it comes to sheet metal fabrication, there's no denying that every project can be unique. Whether that be a multi-layer logo or any other custom product, that is always going to hold true. With the Omax machine mentioned above, our team is able to access a cutting range of 0° to 60°, and cut everything from beveled edges and angled sides to countersinks and essentially any complex 3D parts.

Likewise, it is also able to cut a wide range of different material types, as well as at varying degrees of thickness. For metal thickness, it can cut up to 4". In terms of materials, this includes your standard metals, along with composites, glass, plastics and even wood. By the way, did you know we can even do engraving with the waterjet?

It should come as no surprise that production speed is critical. You have deadlines that need to be met and we're here to ensure your entire experience goes flawlessly. With that in mind, perhaps the greatest advantage tied to working with a state-of-the-art waterjet machine like the Maxiem 1530 is the cutting speeds.

In comparison to other abrasive waterjet machines currently on the market, the difference is substantial. All of this allows our team to ensure we can meet any order sizes from our clients. Additionally, you'll notice that this particular model also can cut materials that don't need much, if any, secondary finishing, thus making the production process even more efficient! As such, this makes the entire process that much more affordable for our clients.

Accuracy and precision are no-brainers for any sheet metal fabrication/cutting project, right? With the multi-axis waterjet capabilities at Wil-Clair, accuracy and quality are always emphasized, including there being no molecular destruction or heat displacement. This helps ensure none of the actual properties of the metal are altered in the cutting process. To add to it, our skilled craftsman know this machine inside-and-out. With their knowledge of the product, you can rest assured knowing the finished product will be spot on!

Behind-The-Scenes Look At The Omax 1530.

If you're not already convinced of what is possible with five-axis waterjet cutting, we thought we would give you a behind-the-scenes look. Check out the video below to see the Omax Maxiem 1530 in action. To request a free quote for your own project, fill out the form HERE and a member of our team will be in touch.

Utilizing the Five-Axis to Cut at 15-Degree Angles.

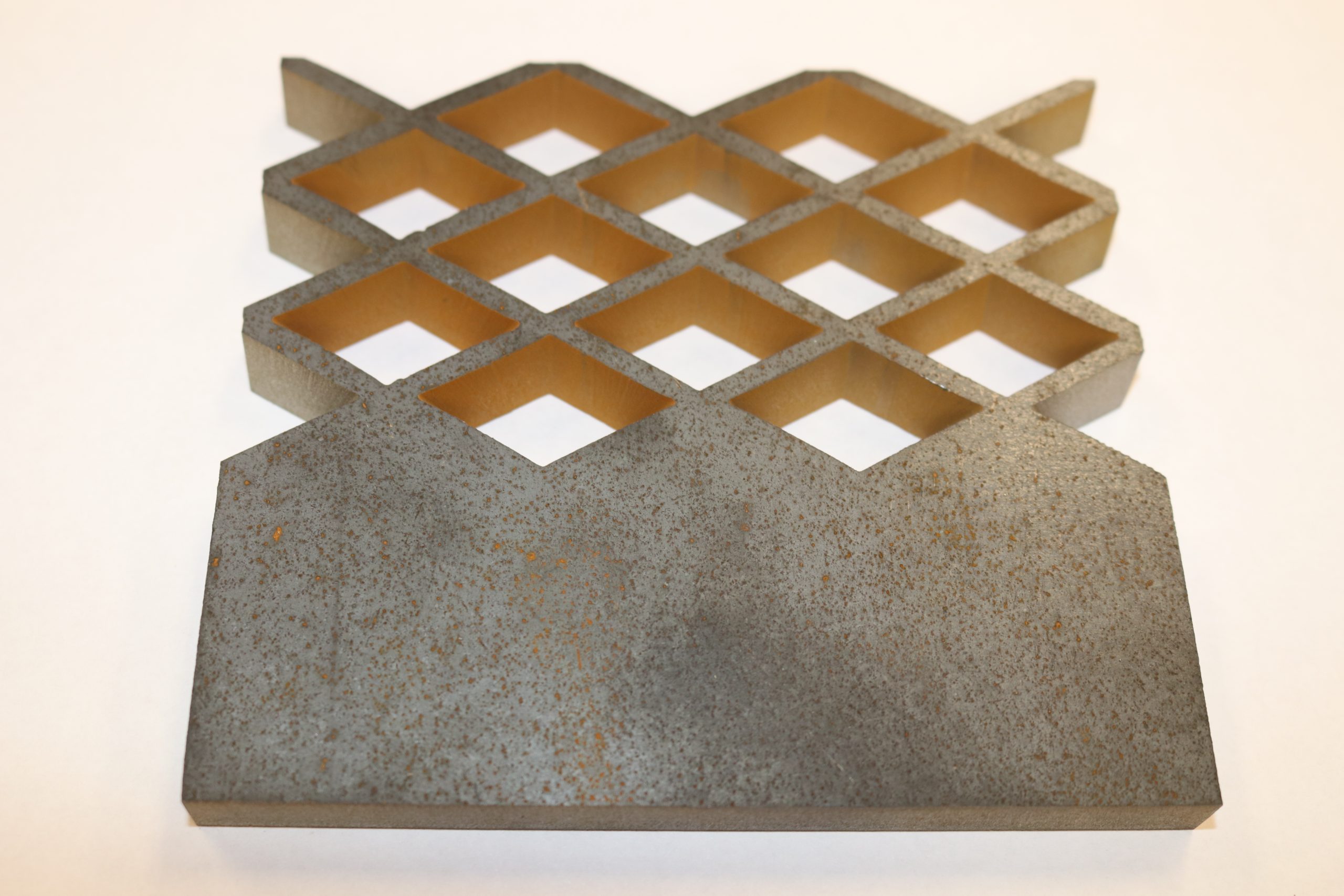

As mentioned above, the five-axis waterjet machine used by our team at Wil-Clair Sheet Metal allows for an unparalleled flexibility on the finished products it creates. One perfect real-world example of this is the ability to cut at detailed 15-degree angles (while still being capable of going up to 60-degree angles). Pictured below is a sample piece our team produced displaying this. This part, in particular, was programmed through 6 different languages. Long story short, if you have a complex project that requires the utmost attention to detail and precise cuts, then the five-axis waterjet machine is the way to go!

- 15-Degree Cuts from 5-Axis Waterjet

What Else Is Possible With Waterjet Technology?

Being a one-stop shop for all things sheet metal, it's safe to say that every project that walks through our doors has the potential to be unique in its own way. Whether that be for a large company requiring significant fabrication work or a local individual simply wanting a sign made for personal use, the possibilities are endless! We've already highlighted a few of the benefits provided by our five-axis waterjet machine thus far. However, two more features of this advanced technology is the ability to precisely cut very small figures, as well as any engraving work needed. Both of these can come in handy for a variety of different purposes! For a quick snapshot of this, check out the sample pieces below.