Inside Look at a Completed Project.

As a shop offering custom fabrication services, it's safe to say we have had the opportunity to work on a wide array of projects over the years! Thanks to this experience, our team has been able to fine-tune our processes for going from initial design to finished product. In late-2022 and early-2023, we helped out with a project at a local Catholic Church here in Kansas City called St. Patrick's Parish.

From fabricating the beautiful baptismal font itself to cutting accent pieces in tile and more, we're excited to share several different stages of this project. Thank you to everyone that worked on this remarkable transformation in KC! On this page, we will highlight the fabrication of the baptismal font. If you're interested in learning more about the tile cutting aspect though, feel free to click the button below.

Baptismal Font Fabrication.

Without a doubt, the featured piece on this project was the baptismal font. Having several different elements involved in its fabrication, this was certainly a fun one to see take shape!

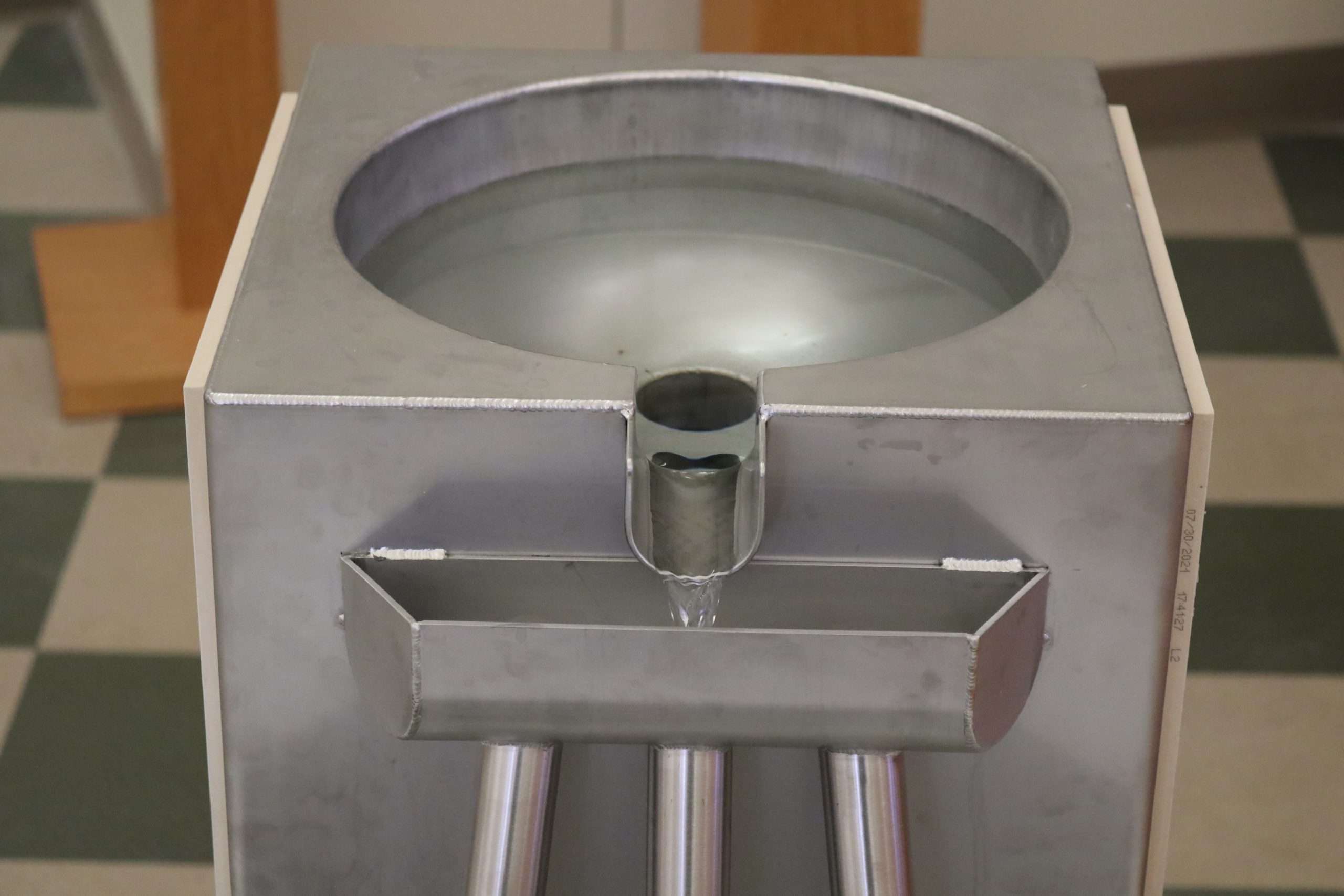

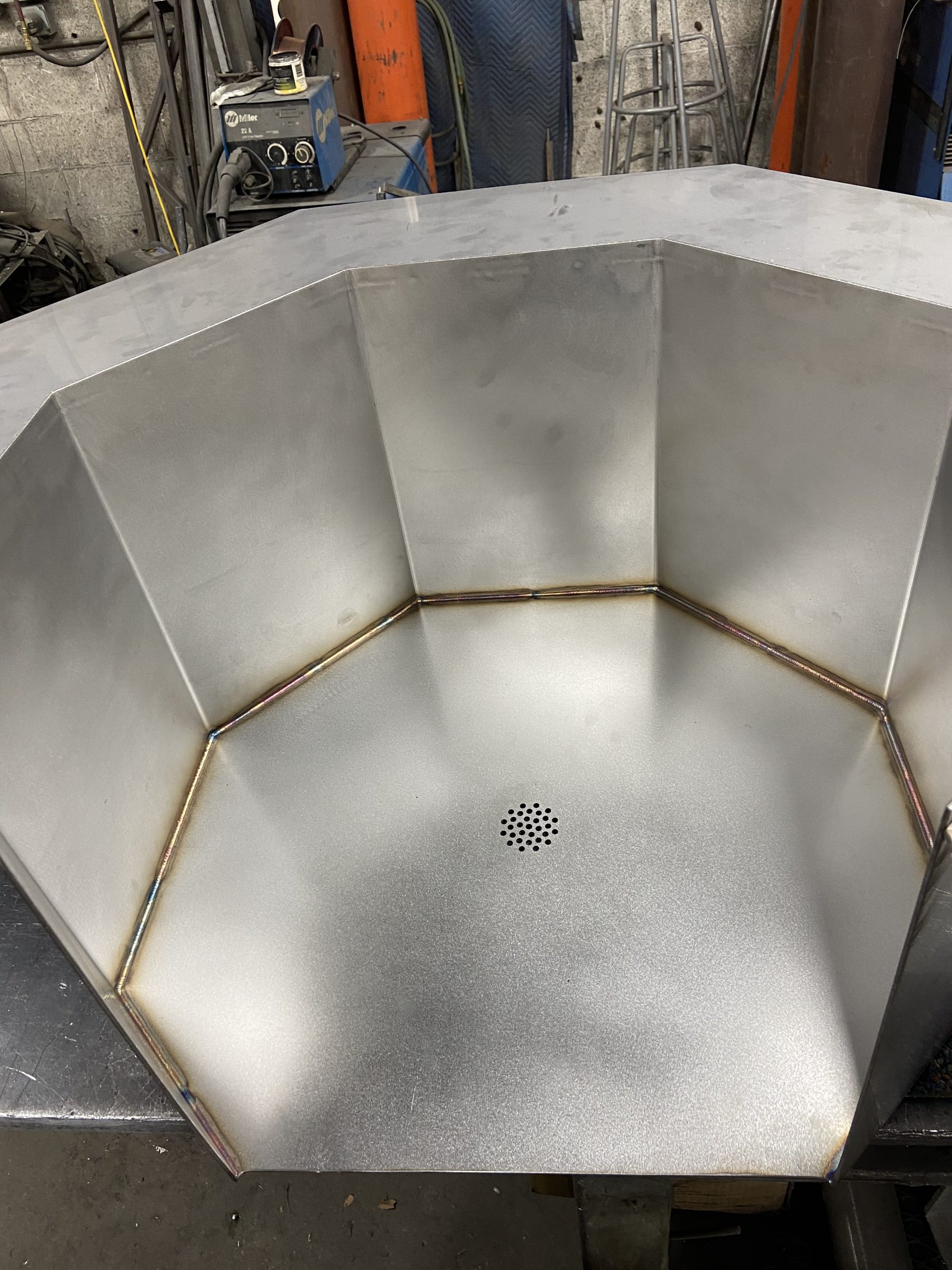

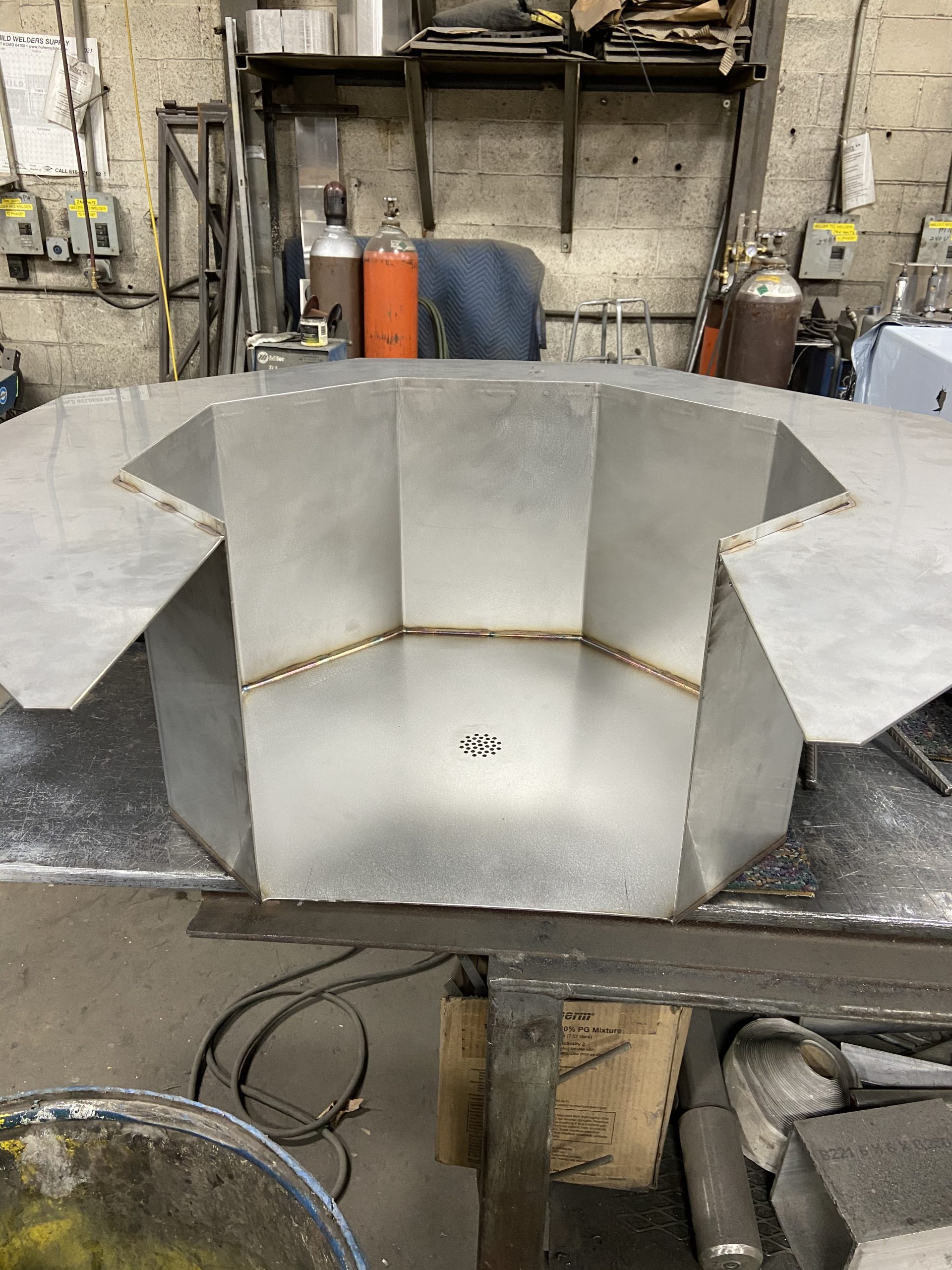

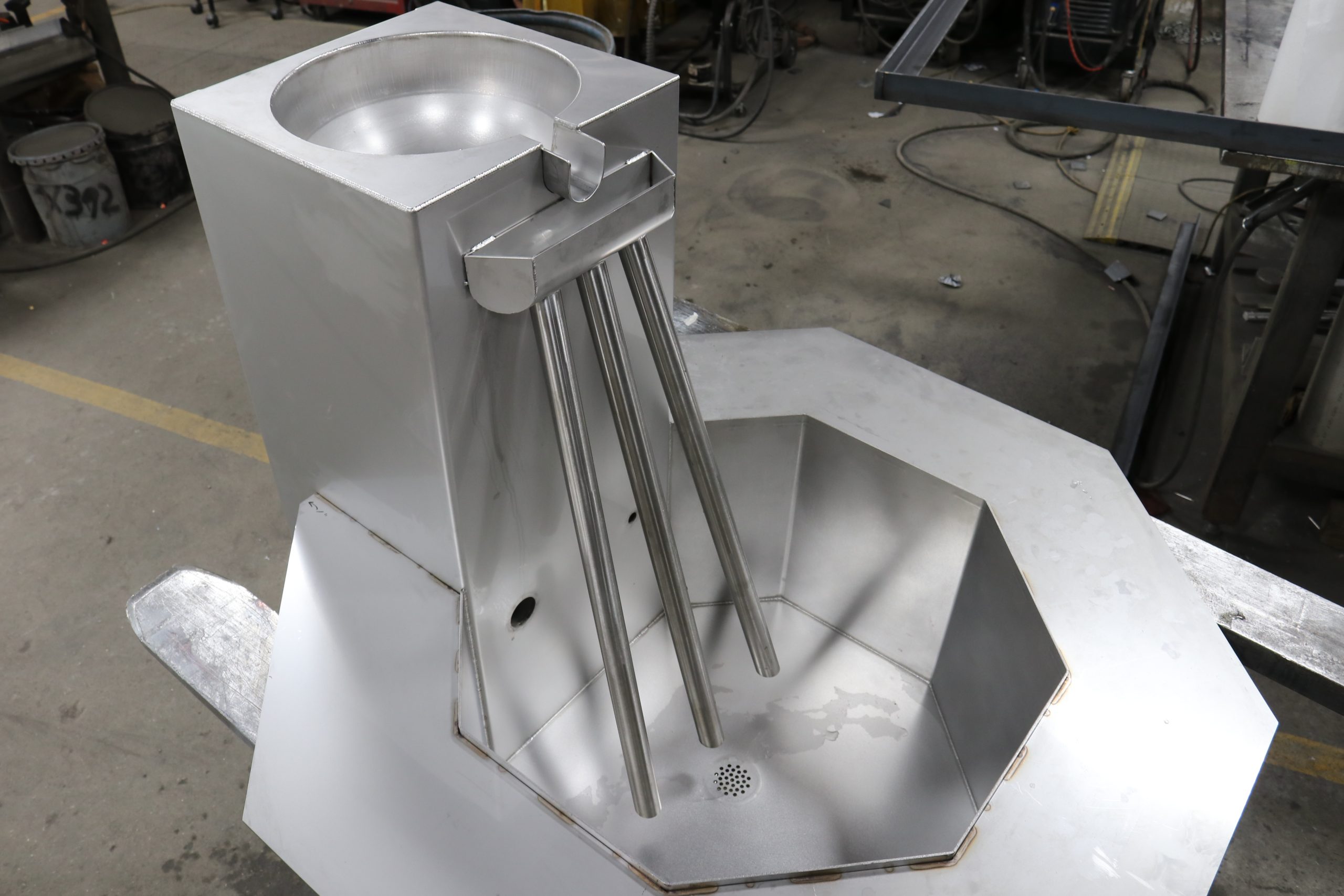

During the earlier stages of the process, you'll see two separate aspects featured below. The inlet and outlet piping was completed through the use of heliarc welding. Meanwhile, the inner tub of the font has been welded to water-tight specifications. The inner tub is made out of 100% stainless steel and all of the parts were cut via the five-axis waterjet machine.

With the ability to achieve a cutting range of 0-60 degrees and being able to cut many different materials, there's a reason why waterjet cutting has been so popular amongst many of our customers!

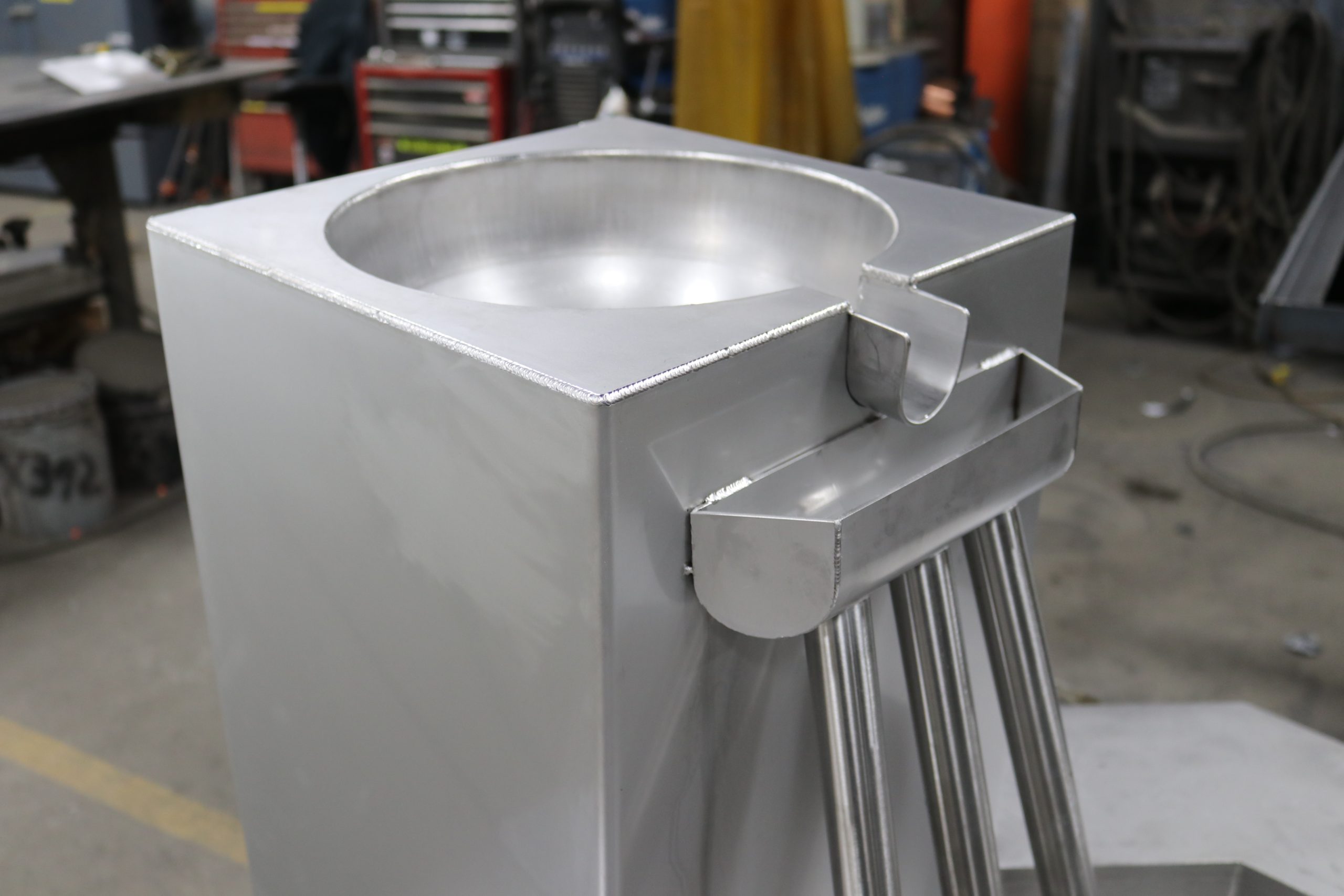

Once the tower was completed, everything was assembled together with the necessary piping included as well.

One more step before we head to St. Patrick's! With the tub and tower connected now, the font was ready for the outer skin, which would be constructed from 3/16" aluminum. As you'll see in the photos, there is a dove with an olive branch on the outer skin as well. This component was engraved to a depth of 1/32" before being painted in a contrasting color. After the outer skin was secured, we completed our final touch-ups and it was now ready to go!

By the way, can you see the sneak peek of where the tile inlay will soon be installed on the font?

Time for the installation at the church! After the core-drilling was finished, it was time for our team to deliver the completed font and then install the tile inlay cut-outs on top of the inner tub. The drain pipes were then run down below and connected to the pump. After that, the baptismal font was officially finished and filled with holy water.